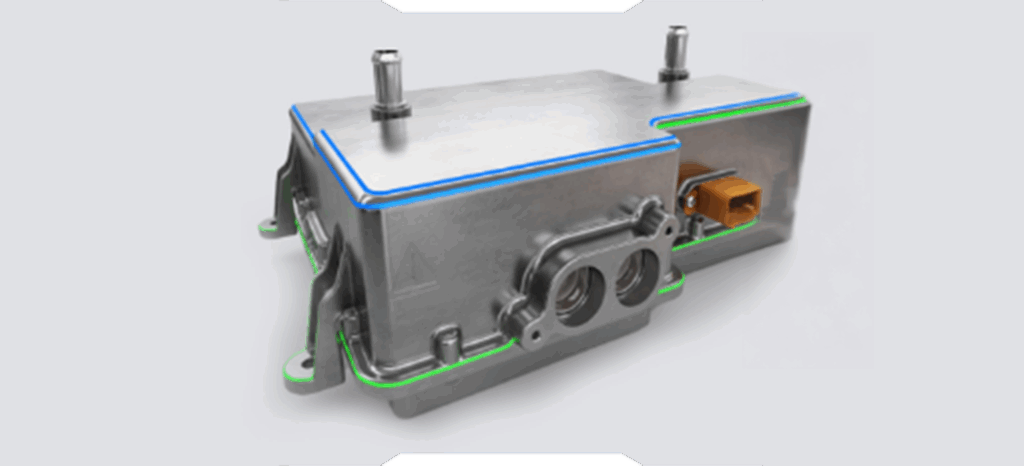

Master Thermal Management at High Power Density in your Traction Inverter

As demands for compact designs and higher power densities increase, effective heat dissipation becomes more challenging. Efficient cooling strategies, such as liquid cooling and integrated cooling channels, are critical to prevent overheating and performance losses.

Why Heat Is the Bottleneck

With rising DC-link voltages (800 V), higher switching frequencies, and increasingly compact designs, traction inverters face significantly growing thermal challenges. Achieving target values above 100 kW/L is only possible if thermal management is addressed consistently from the start. Optimizing here not only saves weight and cost but also extends the overall system lifetime.

Power Modules: Cooling Path Matters

The choice of cooling concept is the first major lever. Double-sided cooling (DSC) reduces thermal resistance Rth‑JC by up to 40% compared to single-sided cooling. The result: smaller chip area, more compact modules, and lower parasitic inductance.

Pro Tip: Include the RC models (Zth(t)) of the module in your simulation for your traction inverter. This allows you to realistically map thermal limits and develop protection strategies based on actual junction temperature.

Thermal Resistances in Detail

- Sintered silver instead of solder improves power-cycling robustness and enhances thermal conductivity.

- Phase-change TIMs prevent pump-out and keep thermal resistance stable - a key factor for reliability.

Cold-Plate Design: More Than Just Cooling Channels

For single-sided cooling, pin-fin plates offer a proven compromise between pressure drop and heat dissipation. For DSC stacks, jet-impingement solutions are recommended, reducing thermal resistance by up to 50%.

Important: Define a Δp budget early and account for particle gaps to avoid surprises later.

Packaging & Qualification

Electrical details also impact thermal performance. Lower busbar inductance reduces switching losses and thus heat generation. Additionally, plan for AQG 324 (Release 04.1/2025) requirements early, especially the extended tests for SiC modules.

Validation Under Real Conditions

Use mission profiles instead of constant load. Only then will your lifetime models reflect reality. Also check TIM layer stability after thermal cycling and ensure thermal balance between parallel chips.

Key Facts at a Glance

- DSC vs. SSC: Up to 40% lower thermal resistance.

- Jet impingement: 20–50% better heat dissipation.

Design Review Checklist

- Is Tj,max defined and included in the model?

- Cooling strategy and Δp budget documented?

- TIM process validated?

- AQG 324 plan aligned?

- Mission profiles considered?

Bottom Line: Thermal management is not a side issue—it’s the key to high power density and reliability. Those who make the right decisions early save development time and cost—and secure performance for the next generation of e-mobility systems.

Do you have any questions or need help selecting the right products for your application? Please feel free to contact us. We will be happy to help you.